Spray cooling system

Typical application places of flue gas cooling system: thermal power plants, urban waste incineration stations, dry arsenic collection in non-ferrous metallurgy, blast furnace gas cooling, converter gas cooling, and exhaust gas cooling at the kiln tail of dry cement production lines/Humidification and cooling of pipelines.

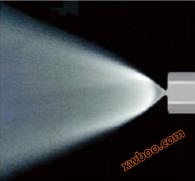

DLA series dual fluid spray gun gas conditioning system

Design features:

1.The atomized particles are very small, with an average diameter of 70-80 microns. Ensure 100% evaporation and keep the bottom dry;

2.A single nozzle has a large water volume, and the water volume adjustment ratio can reach 10:1. Within the range of water volume changes, the atomized particles remain basically unchanged, ensuring that the bottom is not wet under high water volume;

3.Spray has a large coverage area, and the diameter of spray can reach 3-4 meters, which is more conducive to the cooling and tempering of flue gas. The system has low operating cost and significant energy saving. Generally, the working pressure is 3-5 bar, the working water pressure is 4-7 bar, and the pressure resistance level of the system is 16 bar, not more than 250 bar;

4.Grouping control box for single spray gun control: Multiple spray guns under the system can be individually controlled through the grouping control box, which can meet the needs of adjusting the spray volume in a larger range under different working conditions, while also reducing air consumption.

5.Special control to avoid nozzle blockage and corrosion: The control program of the system can greatly prevent nozzle blockage and corrosion problems, thereby greatly reducing the maintenance and repair costs of the system. The average maintenance cycle for nozzles is six months.

6.Multiple working modes: The system has multiple working modes such as automatic mode, bypass mode, and shutdown mode, which can ensure the safe and reliable operation of the system and reduce manual operation.

7.Flexible control and strong compatibility: The system adopts PLC automatic control technology, which can provide complex control functions according to process requirements and can be flexibly modified on site. In addition to operating the system on site, the system can also be connected to the central control to achieve remote control.

Industry ApplicationsofCement Industry

Humidification and cooling of kiln tail gas humidification tower/pipeline in dry cement production line

The flue gas cooling and conditioning system, with high stability and reliability in operation, has become the choice for domestic cement production lines. Moreover, the pipeline humidification and cooling process developed in collaboration with relevant cement design institutes has also performed well, greatly reducing initial investment costs and footprint by eliminating the need for humidification towers.

Industry Applicationsofsteel industry

Evaporative cooling of blast furnace gas, converter gas, and electric furnace flue gas

The spray cooling of the clean gas before the dry dedusting of blast furnace gas enters the gas holder can be realized by spraying small droplets in the gas pipeline with a dual fluid (helium) atomizing nozzle, which can quickly cool the gas. For gas containing high chloride ions, we also achieve dechlorination and cooling by injecting a certain concentration of alkaline solution.

The dry dust removal of converter gas involves fine mist droplets sprayed through external steam nozzles in the evaporative cooler. Within a short period of contact with high-pressure gas, the droplets absorb sensible heat from the flue gas and vaporize completely, thereby controlling the temperature and humidity of the gas and ensuring effective dust collection by the electrostatic precipitator.

The useful nozzle cooling of electric furnace flue gas has obvious advantages over water cooling and air cooling, such as saving water, electricity, reducing floor area, and greatly reducing investment costs. Through spray in the cooling tower or pipeline, the wet wall phenomenon is completely avoided, and the control of flue gas temperature and humidity is realized, which is more conducive to the dust collection of the bag filter.

Industry ApplicationsofEvaporative cooling of the rapid cooling tower for arsenic waste incineration in non-ferrous smelting

The common characteristics of non-ferrous smelting and waste incineration flue gas are high temperature, strong corrosivity, rapid and frequent changes in flue gas volume, which add difficulties to spray cooling. Through years of project practice, we have explored a set of solutions, completely overcome the problems of high temperature resistance, corrosion resistance and high control requirements, and have been successfully applied in the processes of arsenic rapid cooling in the non-ferrous industry, dioxin rapid cooling in removal in the waste incineration industry, and so on.